Details on corrective action that should be taken if your PFM is not displaying a flow rate.

The Smart PFM has a mechanical oval gear flow meter on the sample outlet of the measuring cell. This is a very high precision flow meter to ensure that the sample flow rate is always within operating limits.

If debris or large particles are pumped through the Smart PFM measuring cell, the oval gears can become jammed, resulting in a 0.0 LPM flow reading and your alarms to be stuck in the ON position, preventing any discharge.

The first step that should be checked is that sample is actually being passed to the measuring cell. If the flow meter is blocked, the pressure reading at the display will usually rise above its normal operating pressure.

If the pressure is low, it is likely that the 3-way valve is blocked or that the sample to the Smart PFM is not adequate. To diagnose this fault, remove the sample inlet pipe from the Smart PFM and check that adequate sample is present. If the Flow and pressure is within the limits specified in the data sheet, it may be necessary to clean or replace the 3-way sample valve.

If the pressure is high, check that all valves after the measuring cell are free flowing and free of blockages. Once confirmed, and the drain is free flowing, the following procedure can be carried out to clear any blockages that may have occurred at the flow meter.

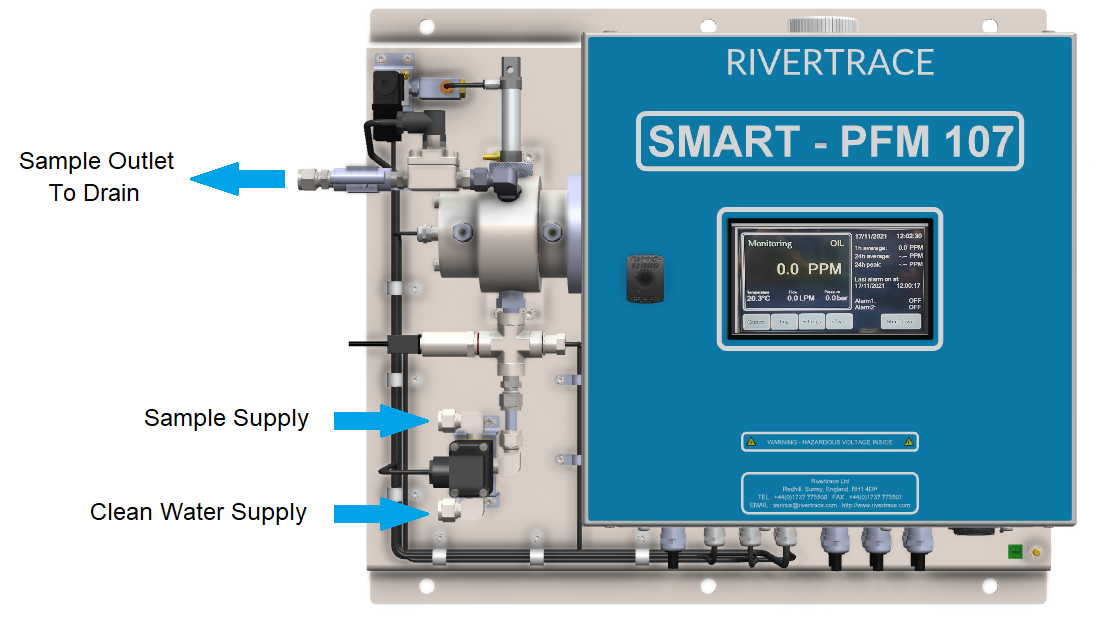

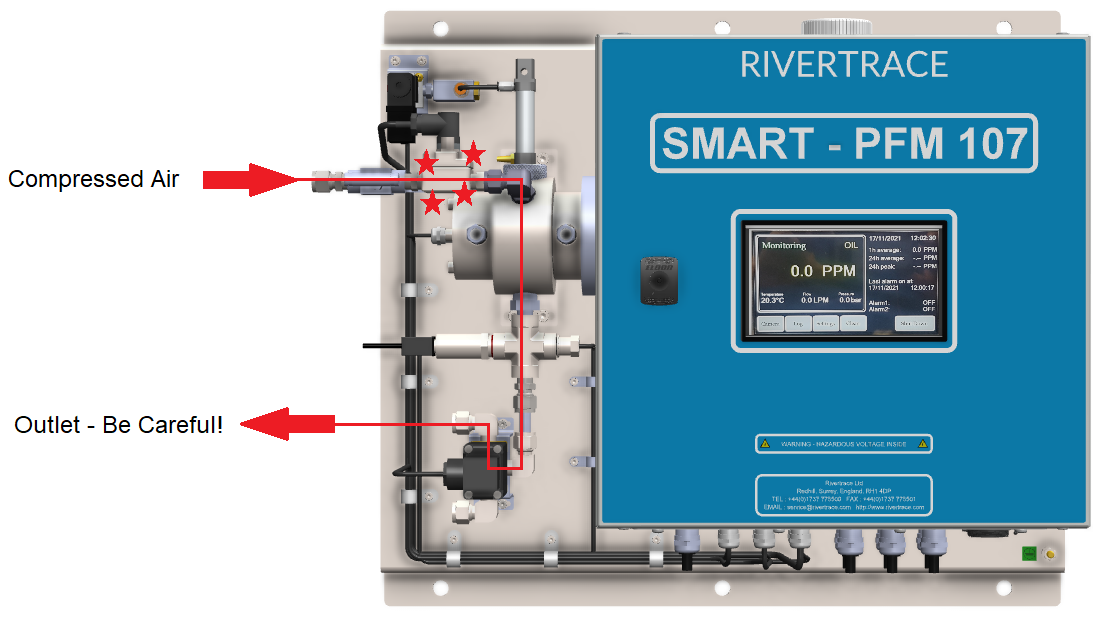

Ensuring that all sample water and clean water supplies are isolated, remove the sample outlet, sample supply and clean water supply customer pipework. This will allow the water to drain. A temporary clean, oil free air supply should then be connected to the sample outlet before short, sharp burst of compressed air are applied. We recommend that safety glasses and ear defenders are used for this process as any debris in the system will leave the system very quickly.

Do not allow the air to run for extended periods, exceeding a few seconds as this could result in damage to the flow meter gears.

If the debris has cleared from the flow meter gears, you should see the flow rate fluctuating at the Smart PFM display.

On completion, all pipework must be refitted in accordance with the Smart PFM operating manual and retested.