Rivertrace MEPC.107(49) Compliant equipment overview and functionality of the Smart PFM107 oil in water analyser.

This is an in depth view of how Rivertrace have responded to marine pollution prevention guidelines with our Smart PFM107 Microscopy based oil content meter.

Rivertrace are world leaders in the measurement of free oil in water.

What is bilge water?

Due to the natural shape and layout of a ship, along with gravity, any spillage, machinery leakage etc. in an engine room or machinery space on board a vessel will mean that the lowest point within that space will accumulate wastewater (Bilge water). This bilge water is predominantly water but due to its proximity to machinery, there is a high chance of oil contamination.

What can the crew do with bilge water?

It is legal for vessels to discharge bilge water back into the ocean providing that certain parameters are met. Uncontrolled levels of oil discharged into the ocean can have a dramatic impact on the environment. Oil cannot dissolve in water and leaves a thick sludge which can endanger marine life and the surrounding environment.

What are the rules?

According to the Marine Environment Protection Committee, also known as MEPC, all ships of 400 gross Tons and above, with a keel laid or a similar stage of construction on or after the 1st January 2005 must operate in accordance with a set of guidelines called MEPC.107(49). This is enforced globally and failure to comply can result in fines in excess of $1million and vessels detained. Marine pollution prevention is taken very seriously.

MEPC.107(49) was adopted on the 1st January 2005 and is still current today after superseding the old MEPC.60(33) regulation that was the standard between the 30th October 1992 and 1st January 2005.

Engineers working with equipment relating to these guidelines must ensure that they are familiar with them to ensure that their work does not impact the compliance of the vessel.

How is it discharged?

New technologies over the last thirty years, such as oily water separators and oil content meters have been developed to ensure vessels can demonstrate compliance to the relevant pollution preventative guidelines.

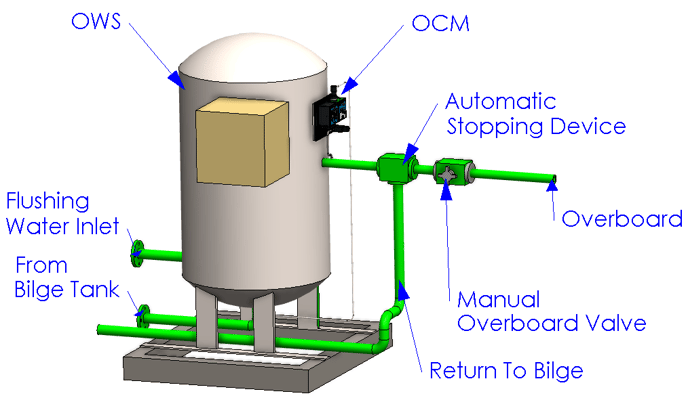

The oily water separator is a piece of equipment that is used to separate oil and water mixtures into their separate components. Oily water separators can be designed to treat a variety of contaminants in water, including free floating oil, emulsified oil, dissolved oil and suspended solids. Oily Water separators, generally referred to as OWS are primarily used for bilge water discharges. The OWS Is typically installed low down in the engine room.

In general, every ship over 400 gross tons will have an approved OWS installed on the discharge pipe between the bilge and overboard. The bilge water is pumped through the OWS, where oil will be removed before passing overboard.

To ensure that the OWS is performing correctly and that a very limited quantity of oil is in the bilge water (Within MEPC.107(49) guidelines), an Oil Content Meter (OCM) is installed to measure the oil content of the bilge water at the separator outlet. This is where the Rivertrace Smart PFM107 Oil Content Meter (OCM) is installed. The Smart PFM107 is an Oil Content Monitor designed, developed, manufactured and serviced by Rivertrace Limited.

The Smart PFM107 will continuously monitor the bilge water being discharged and automatically divert all water back to the bilge tank if the oil content rises above the pre-set alarm point, by controlling an "Automatic Stopping device" (3-way Valve). The standard oil content limit for a legal discharge is 15ppm (Parts Per Million) according to the MEPC.107(49) guidelines. To put this quantity of oil into context, this is 15mL of oil in 1000 litres of water.

With this configuration, discharges are monitored automatically and excess oil is prevented from being discharged. When the oil content exceeds the alarm point (typically 15ppm maximum), the water is diverted back to the bilge tank. This state recirculates the water, continuously stripping oil as the water passes through the OWS until the water leaving the OWS drops back below the alarm point. At this stage, the "Automatic Stopping device" (3-way valve) will open once more to allow the discharge of water overboard to commence. This process will continue until the pump moving the water is stopped, either manually by crew or automatically by liquid level sensors in the bilge tank.

Did you know...

Other MEPC guidelines often recommend the use of MEPC.107(49) approved analysers for applications other than bilge water...

The 2018 Guidelines for the discharge of Exhaust Gas Recirculation (EGR) bleed-off water - MEPC.307(73), is a great example of this, where an approved MEPC.107(49) analyser is required to monitor the bleed-off water from the ships EGR system.

The problem here is that the sample if often far too turbid for the standard scattered light analysers to gain truly accurate measurements.

This is where the Smart PFM107 excels!

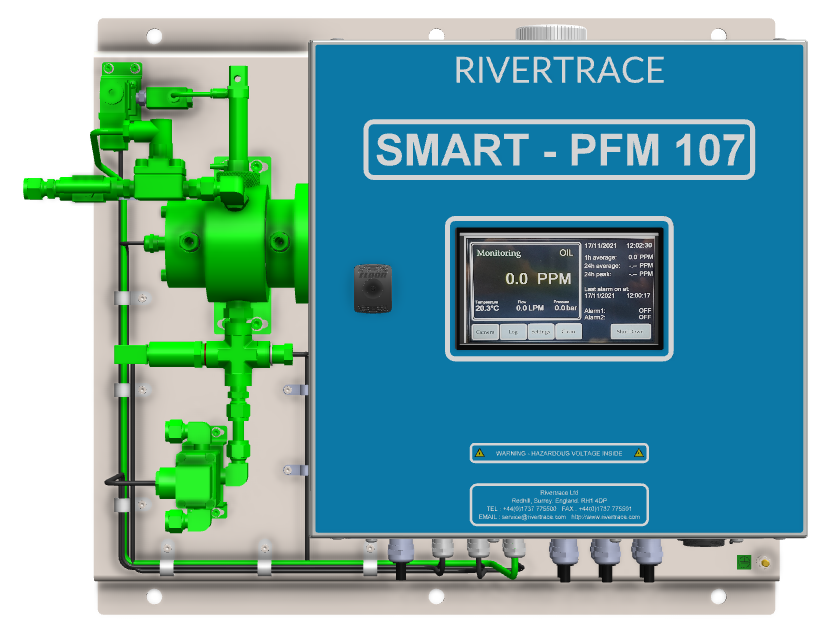

Smart PFM 107 MEPC.107(49) OCM information

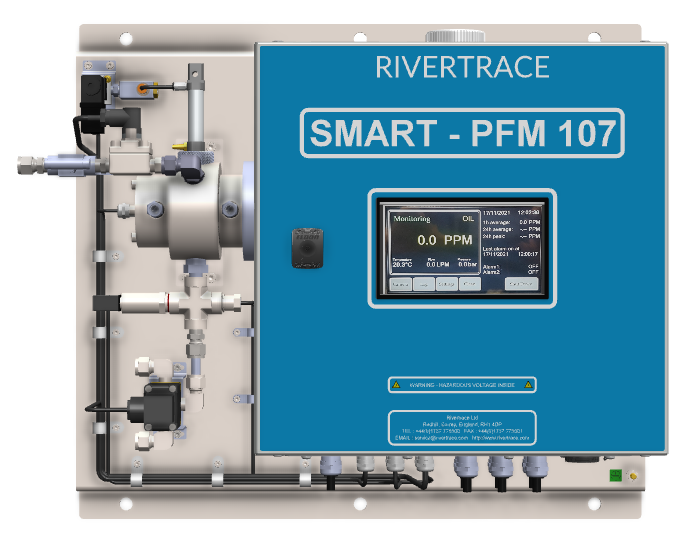

All details regarding the serial number, supply voltage, date of manufacture and approvals can be found typed onto the silver rating label, fixed to the top left corner of the Smart PFM107 backplate.

The Smart PFM107 monitor is split into two modules; the Computer module and the measuring cell.

The controller module, located on the right of the SmartPFM107, performs the following;

- Houses and drives the Display where Time, Date, PPM, alarm states and fault messages are visible.

- Houses and drives the touch screen used to navigate the menus.

- Receives mains power and distributes power to the measuring cell.

- Contains two alarm relays. Alarm 1 (Left Relay) must be used for directly controlling an "Automatic Stopping Device" and Alarm 2 (Right Relay) is used to control an audible alarm supplied by the vessel.

- Drives the sample / Clean solenoid valve as required.

- Holds the Clock and IMO Data memory.

- Has a mA output terminal that will emit an active 4-20mA Output, representing the PPM value, for remote displays.

- Has a switch input that MUST be wired to volt free contacts within the separator that close when the oily water separator is running. This is a legal requirement. This is the "Separator Input Status".

- Holds the Calibration data.

- Houses the microscope used for detecting oil and other contaminants within the sample.

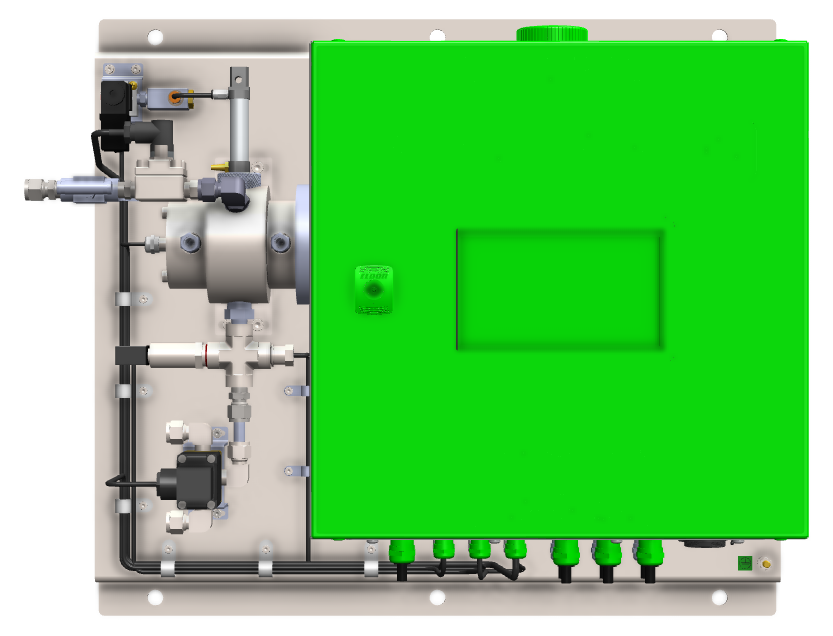

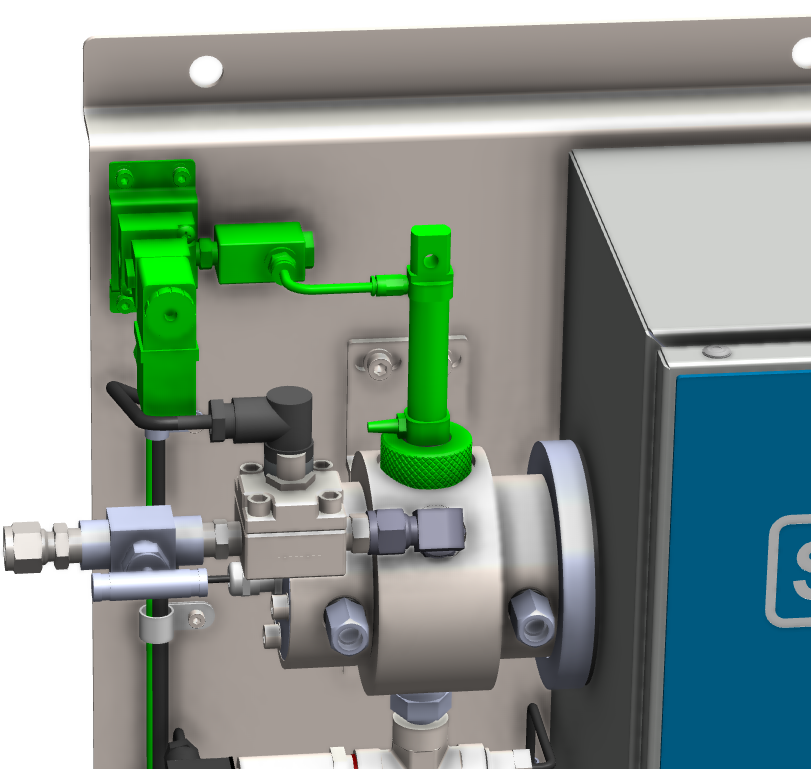

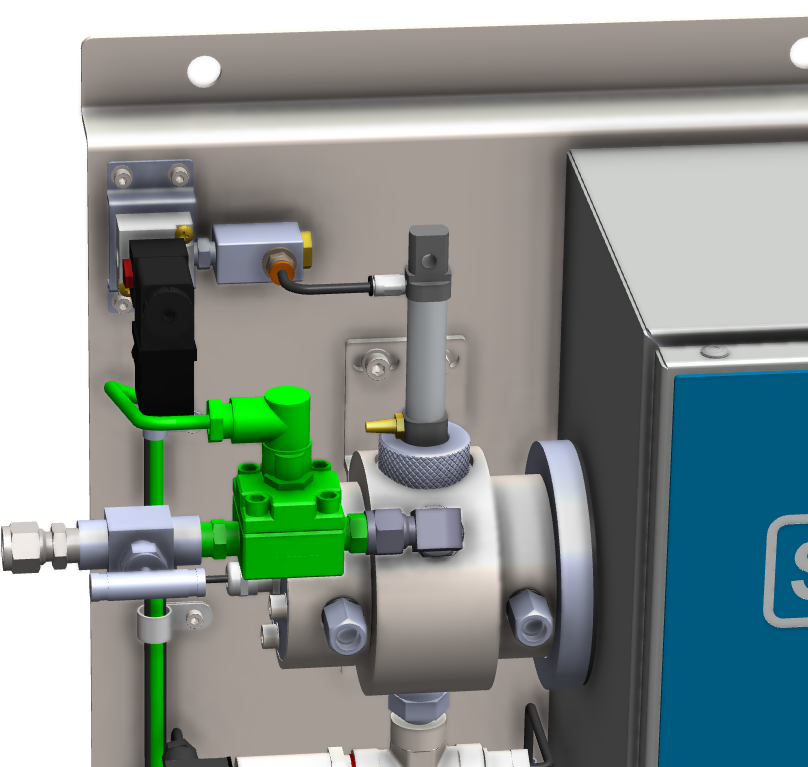

The measuring cell, located on the left of the Smart PFM107, performs the following; All wetted parts are 316 Stainless steel to stand up to harsh environments and samples that are typically too damaging for standard oil-in-water analysers.

- Houses the precision optics to allow the camera located inside the computer module to accurately photograph the oily water sample.

- Houses a blue strobe back light to allow the camera located inside the computer module to accurately photograph the oily water sample with clear and crisp image outlines.

- Houses the flow meter that will measure sample flow passing the measuring cell, tripping the alarms if insufficient flow is detected.

- Houses the pressure transmitter that will measure sample pressure within the measuring cell, tripping the alarms if insufficient pressure is detected.

- Houses a thermistor that will measure sample temperature within the measuring cell, tripping the alarms if the temperature is out of tolerance.

- Houses the Autoclean actuator that is used to ensure that the optical path and sample windows are kept at optimum clarity.

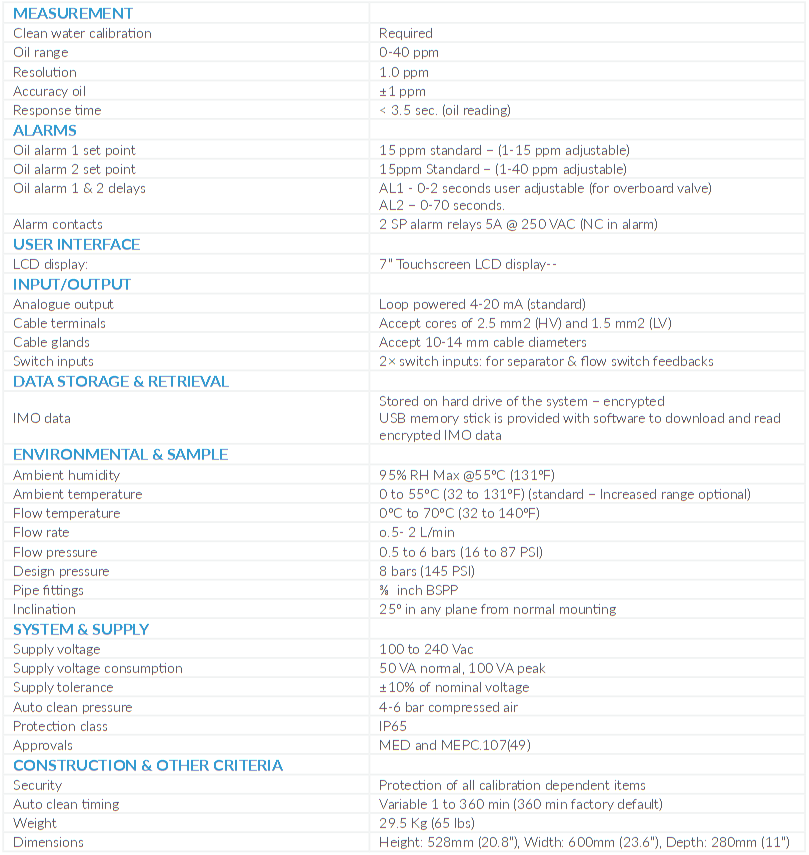

The Smart PFM107 meets and exceeds all requirements set out by MEPC.107(49). The specifications in the table below are for our standard offering.

As with all MEPC.107(49) Oil in water analysers, there are flaws within the regulation that do not protect against malicious or even accidental tampering of the OCM. Rivertrace have identified these areas and have robust solutions in place to bolster the standard Smart PFM107 OCMs security and reliability.

The most prominent cause of OCM failure is undoubtedly soiling of the optical components within the measuring cell. Rivertrace have factory standard accessory to tackle this manufacturer wide problem. A pneumatic Auto-Clean system is fitted to all standard Smart PFM107 analysers to automatically clean the optics on adjustable, timed intervals. With crew already stretched, this system increases service intervals and reduces man hours needed for periodic maintenance.

Another known problem with OCMs on board vessels is that the flow through the measuring cell is rarely checked. This means that it may be possible to trap clean water inside the measuring cell to allow a discharge to take place without measuring the oil content of the actual water leaving the OWS and passing overboard. The result is an unmonitored, illegal discharge. This can occur through a malicious act by OWS operators or due to something as simple as a blocked sample pipe.

Whatever the cause, Rivertrace have a solution in which a flow meter is fitted to the measuring cell outlet. If the flow passing through the measuring cell does not meet the required rates , an alarm is triggered and the automatic stopping device (3-way valve) at the separator outlet is closed to recirculate all flow back to the bilge tank until flow is detected once more.

On top of these enhancements that exceed standard MEPC 107(49) requirements, Rivertrace offer a verification sample kit that can be used by crew to verify and demonstrate the accuracy of the Smart PFM107 measuring cell. Two bottles of fluid are provided per kit allowing the operator to demonstrate the accuracy at both 10ppm and 20ppm. These points have been selected so that they straddle the alarm point which is typically set to 15ppm. The 10ppm verification kit will demonstrate that the Smart PFM107 monitor will allow a discharge when the PPM is below the alarm point. The 20ppm solution will demonstrate that the Smart PFM107 will prevent a discharge should the PPM rise above the alarm point at 15ppm.

The Factory calibration is valid for 5 years. The calibration can only be performed by Rivertrace at the Rivertrace factory or by specially trained and certified engineers on-site, renewing the calibration certificate for a further 5 years.

Why choose Microscopy over traditional oil-in-water measurement techniques?

Although the Smart PFM has very similar function to the Rivertrace Smart Bilge monitor and OCMs from competing manufacturers, the Smart PFM107 is a very different analyser when it comes to performance, primarily designed for applications that call for an MEPC.107(49) approved analyser to be used in applications that fall outside of the standard bilge water discharges.

Typically, there are two main measurement techniques employed to measure oil in water, being UV fluorescence and scattered light. These technologies are very common, with scattered light technology being far more widely utilized, and can perform very well in the right applications.

UV fluorescence is extremely accurate when measuring known oils in known water, often offering +/- 0.1ppm accuracy estimates and better, depending on measurement range. It is important to read the small print with these analysers as the conditions that must be met to achieve these accuracies are typically very difficult to achieve in a real working environment, outside of laboratory conditions. This is ideally suited to drinking water applications and similar, where the composition of the sample is regular and predictable, without unknown contaminants. The downside to this technique is that when unexpected substances within the sample fluoresce, such as cleaning chemicals, soaps and BOP fluids, the UV fluorescence technique can give hugely inaccurate results. High calculated readings can be common and discharges of oil-free fluids can be prevented due to these false readings.

Scattered light is predominantly used in bilge discharge or other dirty water applications where unknown substances may be found within the sample. This technique gives average to good accuracy across a wide range of sample conditions, however, anything that scatters light within the sample has the potential to increase the oil content reading (Solids behave very differently to oils and other light scattering contaminants so can usually be largely ignored by the algorithms calculating the oil content) . Accuracies around +/- 2.0ppm and better are usual and are generally quite reliable when used in the field. If a substance does not change the clarity of the sample, it is unlikely that the analyser will detect the substance as an oil or any other component that will raise the calculated value. The Achilles heel of scattered light measurement techniques is that if the sample contains non-emulsifying soaps, bacteria, algae or other contaminants that alter the turbidity of the sample, the monitor is likely to overread, preventing discharges of fluids that may be perfectly suitable to discharge.

Here is where the Smart PFM, using Microscopy as its measuring technology steps up.

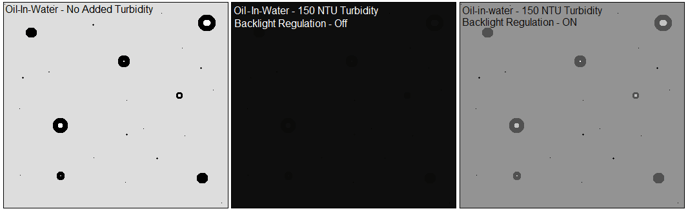

Microscopy excels due to the silhouette of the oil content being visibly identified and measured, the optical clarity of the sample has very little impact on accuracy and is immune to algae, bacteria, dissolved chemicals and dissolved solids hindering the data capturing under the microscope, up to circa 160 NTU.

The Smart PFM107 continuously monitors and regulates the image intensity and sharpness at the digital camera that is obtaining the images of the sample through the microscope. As the turbidity of the sample fluctuates, the power to the backlight strobe increases and decreases to maintain a clear image suitable for shape detection of particles within the sample.

As a high level overview of the method of image analysis, there are three main categories that particles fall into.

Free Oil particles are typically spherical and give a circular silhouette with a dark center.

Solids can appear in many forms and are typically irregular with a dark center.

Gas bubbles within the sample behave like a lens and focus the backlight into a very bright center. Often, the center of a gas bubble is brighter than the surrounding clear water.

This technique offers all of the advantages and positive behaviors of scattered light technology with the additional benefit of handling the turbid water that can usually be found in applications where water may stay static for extended periods of time, harboring algae or bacteria blooms or water that has been contaminated with other chemicals, BOP fluids etc. that will increase sample turbidity up to approximately ~160 NTU. Chemicals and other non-oil based substances that fluoresce will also pass through the Smart PFM107 unnoticed, resulting in a very reliable measuring technique that will not leave the operator with a quantity of water that they cannot discharge due to false high readings.

Where can a bilge discharge take place?

Amongst other factors, the vessel's speed and position dictate when a discharge of bilge water containing less than 15ppm of oil is permitted from the OWS system, according to MARPOL (The International Convention for the Prevention of Pollution from Ships).

As an overview, the below list highlights the key rules set out by MARPOL;

- The Ship is proceeding en route.

- The bilge water has been processed by a suitably approved OWS.

- The oil content of the bilge water is less than 15ppm without dilution.

- The oil content of the bilge water does not originate from cargo pump-room bilges (on board oil tankers).

- The bilge water is not contaminated with cargo oil (on board oil tankers).

Although MARPOL set the international regulation for pollution prevention, this is a minimum. Often nations, regions and even states have tighter restrictions to meet on top of these MARPOL regulations. Some special areas of ocean are protected and no discharges may take place at all.

Ultimately, the ship's crew are responsible for determining if the ship is in a location where a discharge is permissible.

What else happens?

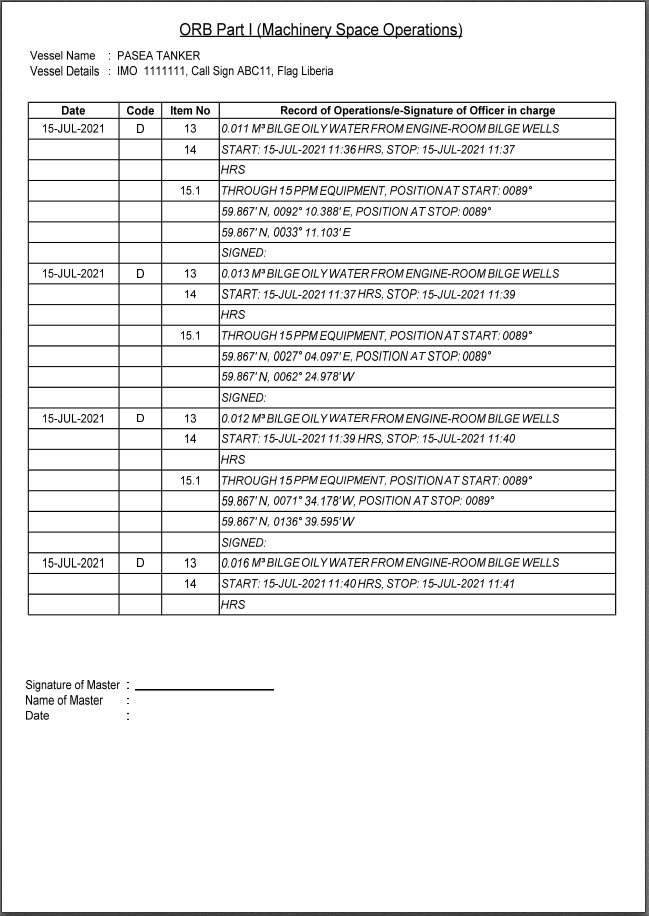

With each movement of oil on board a vessel, an entry must be made into an "Oil Record book". This is effectively a log that tracks the movements of all oil on board a vessel be it within the vessel, boarding the vessel or being discharged from the vessel. This is usually a paper log book that is manually written with a pen. Failure to keep this Oil Record Book accurately maintained will result in large fines, on par with fines for illegal discharging oil. This is the vessels responsibility. Some vessel's and regulating bodies are now starting to adopt digital oil record books as opposed to paper copies.

Alongside the Oil Record Book, the OCM must record key data from each discharge. According to and exceeding MEPC.107(49), the Smart PFM107 records date, time, alarm status, and operating status of the 15 ppm Bilge Separator along with the measured PPM when the log entry was made. The Smart PFM107 can also store data for at least eighteen months and can display it for official inspections as required on board for 18 months. This is referred to as "IMO Data". This IMO Data can also be copied to a local computer if required, in a text format.

Who Checks?

There are numerous ways of illegal discharges or even discharge data discrepancies being highlighted to authorities. Whistle-blowing is one method, where crew may witness illegal discharges taking place maliciously or even accidentally and report it. This is usually financially incentivized by authorities to encourage this to happen.

3rd parties such as neighboring vessels or coastguards may also witness illegal discharges or even the resulting oil spill from an illegal discharge and track which vessel may have been responsible, using the GPS locations of vessels that have been in the area.

The vessel may have accidently performed an illegal discharge and inform the authorities of this, taking the appropriate action to correct the mistake.

Sometimes no discharge is necessary for fines to be issued. Often, data discrepancies between the OCM data, tank levels and the oil record book suffice. These discrepancies are usually picked up by official surveyors who survey vessels each time a port visit is made. In general, the surveyors who board the vessels in port will want to see the Oil Record Book, IMO Data inside the Smart PFM107 and a demonstration of the OCM directly controlling the automatic stopping device at the OWS when 15ppm is exceeded, preventing a discharge in accordance with MEPC.107(49).

Calibration check kits are available for the Smart PFM 107 that consist of two bottles of verification fluid, a verification pipe, a syringe and bottle brush. Each bottle of fluid has an accurately produced sample inside that, once poured into the measuring cell, will demonstrate the accuracy of the analyser. The bottles are 10ppm and 20ppm, straddling the alarm point.

When 10ppm fluid is poured into the cell, the alarms should be OFF and the display should read between 7ppm and 13ppm.

When 20ppm fluid is poured into the cell, the alarms should be ON and the display should read between 17ppm and 23ppm.

Calibration is required if the Smart PFM displays outside of these limits.

Support

Alongside our expansive agent network, Rivertrace are embracing digital and all it has to offer. One aspect of this that is proving invaluable is our ever growing "Knowledge base", which is published on our website. The vast majority of queries from vessels, service engineers and others, outside of and within Rivertrace are published and explained here. This area is dedicated to "How To" guides, fault finding instructions, standard procedures and expert advice.