Sample Conditioning Units (SCU)

Selecting Rivertrace Sample Conditioning Units (SCUs) for industrial OIW analysers, the part they play and their advantages.

Overview

Rivertrace analysers are designed to detect ‘Suspended’ or ‘Free oil’ in water. For maximum accuracy, consistency and reliability, the sample should have an even oil particle distribution within the water and each oil particle should be similar in size between 1 and 20 microns.

Gas bubbles should be removed at any opportunity and prevented from entering the flow as early as possible. The optimum sample pressure is approximately ~3 bar across our Industrial range of analysers. If the pressure is lower than ~1 bar, optical analysers can be susceptible to interference from very small air bubbles and cavitation that could be within the sample. Increasing the cell pressure will compress problematic bubbles within the sample and allow them to pass through the measuring cell with little to no impact. There is limited benefit of increasing the sample pressures above 4 bar as this has diminishing positive affect on measurement, although will not do harm unless the sample pressure exceeds the rated pressure of the measuring cell.

The Rivertrace Sample conditioning units (SCUs) are designed, developed and tested to condition the sample, giving the oil content analyser the optimum sample conditions for analysis. A static mixing head (a Special Rivertrace design) uses a jet of the sample at specific high pressure to ‘break’ the oil into the water. The jet of water is forced into a flat surface at high velocity where the oil is evenly distributed into the water with an even particle size.

The pressure drop across the mixing head is crucial for an even particle size. After extensive development and testing, we have found that a pressure drop of ~7 bar produces the best mix of oil in water. If the pressure drop is too low, the sample becomes uneven and potentially unstable under certain circumstances.

Rivertrace SCU systems are available for use in both potentially hazardous and safe areas. The wetted parts are also available in a range of exotic materials whereas the pump head is available in 316L Stainless steel, brass and PEEK.

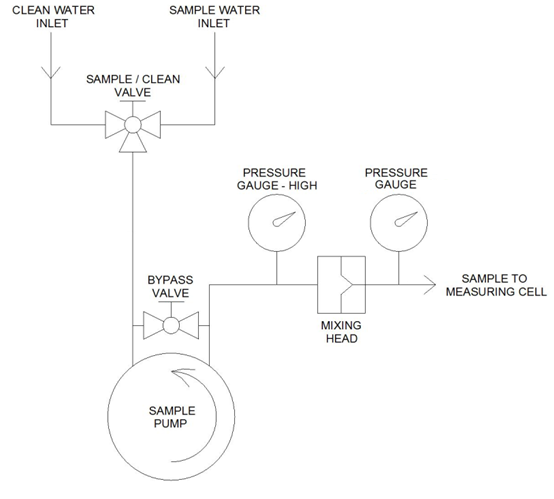

Sample pressures up to 5 bar (Inclusive)

We advise fitting an SCU with a sample pump, pressure gauge and mixing head.

Purpose of components:

Pump - To increase the sample pressure to 12 bar +-1 bar before the mixing head giving a pressure of 3 to 4 bar after the mixing head at the measuring cell.

Mixing head - The mixing head is used to evenly distribute the oil within the sample.

Pressure Gauges - To check that the mixing head pressure differential is correct.

Pressure Switch - A pressure switch will stop the motor if the pressure exceeds a set limit to protect the pump and analyser. The pump will also stop is low pressure is detected to prevent dry running.

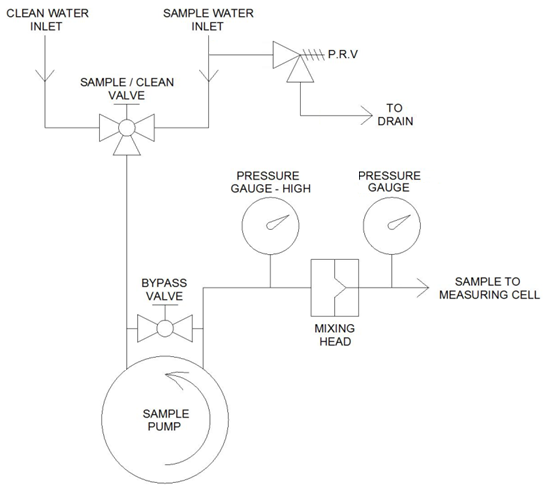

Sample pressure of 6 - 11 bar (Inclusive)

We advise fitting an SCU with a sample pump, pressure gauge, inlet pressure relief valve (PRV) and mixing head.

Purpose of SCU:

Inlet pressure relief valve - To regulate the inlet sample pressure at the pump. A PRV is used instead of a regulator as a regulator will restrict the flow rate of the sample line, potentially cause pump cavitation or oscillation and increase response time.

Pump - To increase the sample pressure to 12 bar +-1 bar before the mixing head giving a pressure of 3 to 4 bar after the mixing head at the measuring cell.

Mixing head - The mixing head is used to evenly distribute the oil within the sample.

Pressure Gauges - To check that the mixing head pressure differential is correct.

Pressure Switch - A pressure switch will stop the motor if the pressure exceeds a set limit to protect the pump and analyser. The pump will also stop is low pressure is detected to prevent dry running.

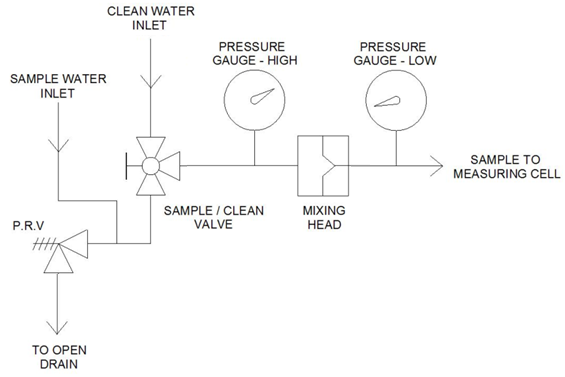

Sample pressures exceeding 12 bar (Inclusive)

We advise an SCU that consists of a mixing head with gauges, inlet PRV and fittings only.

Purpose of SCU:

Mixing head - The mixing head is used to evenly distribute the oil within the sample. As the sample pressure exceeds 12 bar, no pump is needed to force the sample through the missing head.

Pressure Gauges - To check that the mixing head pressure differential is correct.

Inlet pressure relief valve - in case of system upset, for safety purposes only.

Customers with a sample pressure of 15 bar and over.

We advise an SCU that consists of a mixing head with gauges, 14 bar inlet pressure relief valve (PRV) and fittings only.

Purpose of SCU:-

Mixing head - The mixing head is used to evenly distribute the oil within the sample. As the sample pressure exceeds 12 bar, no pump is needed to force the sample through the missing head.

14 bar inlet pressure relief valve - To regulate the inlet sample pressure of the mixing head to 14 bar with a pressure relief valve that vents excess pressure to the system drain. A PRV is used instead of a regulator as a regulator will restrict the flow rate of the sample line and increase response time.

Pressure Gauges - To check that the SCU is behaving correctly and that the mixing head nozzle is not blocked.