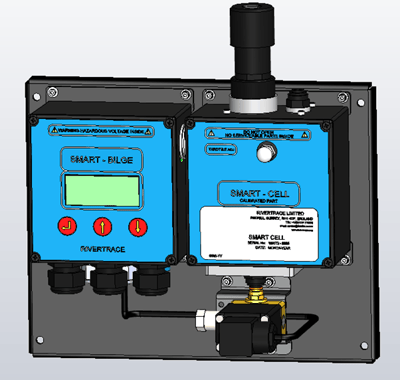

Smart Bilge measuring cell cleaning

A guide on how to clean your measuring cell if high or inaccurate readings are experienced.

Cleaning the cell is a simple process that requires only a bottle brush and a mild acid such as orange juice, vinegar or cola. These acids are preferred as they are safe to both the operator and the equipment. All power, air, sample and fresh water must be isolated prior to cleaning the measuring cell.

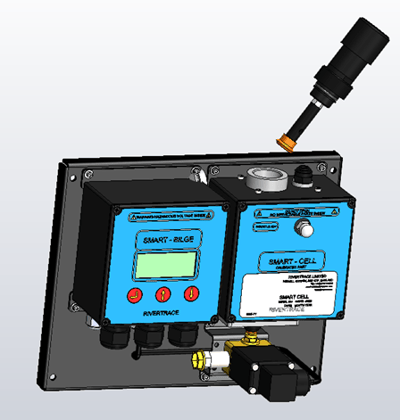

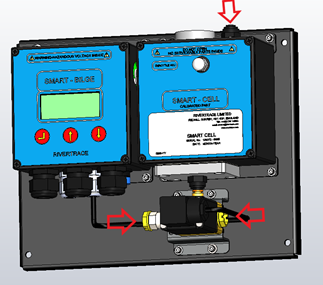

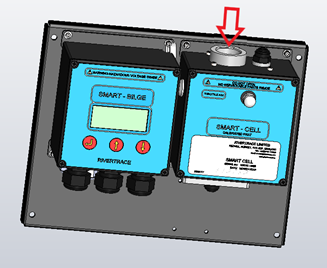

Once all supplies are isolated you can drain the cell and remove the Autoclean/manual clean from the top of the cell and plug the inlet and outlet. This can be performed using a small rubber bung or plastic blanking plugs supplied with the monitor from new.

The measuring cell can now be filled with the mild acid such as orange juice, vinegar, cola or the Rivertrace cleaning kit. This is safe to both the operator and the equipment. This should be left for a minimum of 12 hours before cleaning the inside of the glass tube with a soft bottle brush. The measuring cell cover should never be opened to prevent irreparable damage and void of warranty.

Once the cell is cleaned with a soft bottle brush, drain the cell and refit all pipework and Autoclean/Manual clean. Please note that this should not be fitted too tightly. This should be screwed in by hand fully and then backed out by 1/2 to 1 full turn.

Now flush with fresh water for around 30 minutes. This will flush the measuring cell and properly and also flush the fresh water supply line to the SmartBilge monitor which are prone to corrosion / debris build-up through sporadic usage. Once flushed, ensure the PPM has decreased to a suitable level of 0ppm.

It is crucial that fresh water lines are always flushed properly. Never assume that the water leaving the ships fresh water supply is clean instantly.

Often the fresh water supply is dirty until properly flushed. In some cases, air or other contaminants may remain present even after flushing. This needs to be highlighted and resolved by the ship.