Plunger down detected (Smart Bilge)

Detailed explanation of what causes the "Plunger Down" Error and possible solutions.

The “PLUNGER DOWN DETECTED” error is displayed when the infer red light from the LED is no longer received by the detector array. This can be caused if the manual clean wiper (plunger) is stuck in the down position or there is a high quantity of air, oil or solids etc in the sample that can obstruct the light. Staining or debris on the inside of the glass tube can also cause plunger down.

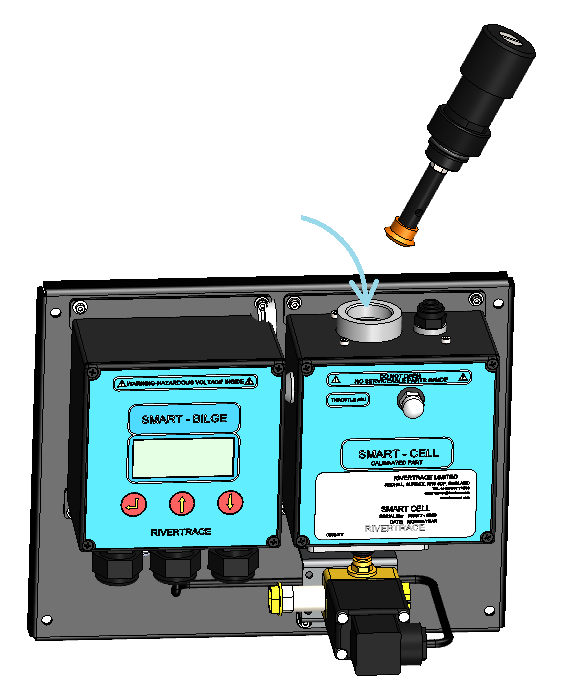

The first check should be to see if there are any blockages visible inside the measuring cell by isolating all flow, removing all pipe work and plugging all holes. The manual clean wiper should be removed and you should visibly check that the measuring cell tube is clear.

The next step is to make sure the sample is not heavily soiled or bubbly. If the sample appears to contain air, high amounts of oil or solids, the cause of this should be addressed at the separator.

To eliminate the possibility of a poor sample, bottled water should now be poured into the measuring cell via the manual clean wiper hole.

You should place your hand or opaque object over the manual clean hole to stop any external light entering the measuring cell and interfering with the detectors. If the monitor doesn’t read between 0ppm and 3ppm then the Smart bilge measuring cell should be cleaned in accordance with the Smart bilge measuring cell cleaning procedure.