Smart ODME Bucket test

To test the functionality of the ODME system without slop water available, a bucket can be used in the place of slop water.

It should be noted that the overboard discharge valve will open during this test so you need to ensure that the final manual overboard discharge valve is locked shut to prevent any discharges into the sea. You also need to ensure that you have permission from the Captain/Ch Officer for the test you are about to carry out.

Materials needed:

- Empty drum or container (45 gallon oil drum type is ideal if available).

- Flexible hoses.

- Suitable, safe and clean test oil such as WD40 or cooking oil.

- Fittings to connect the hose to the connections on the VPC.

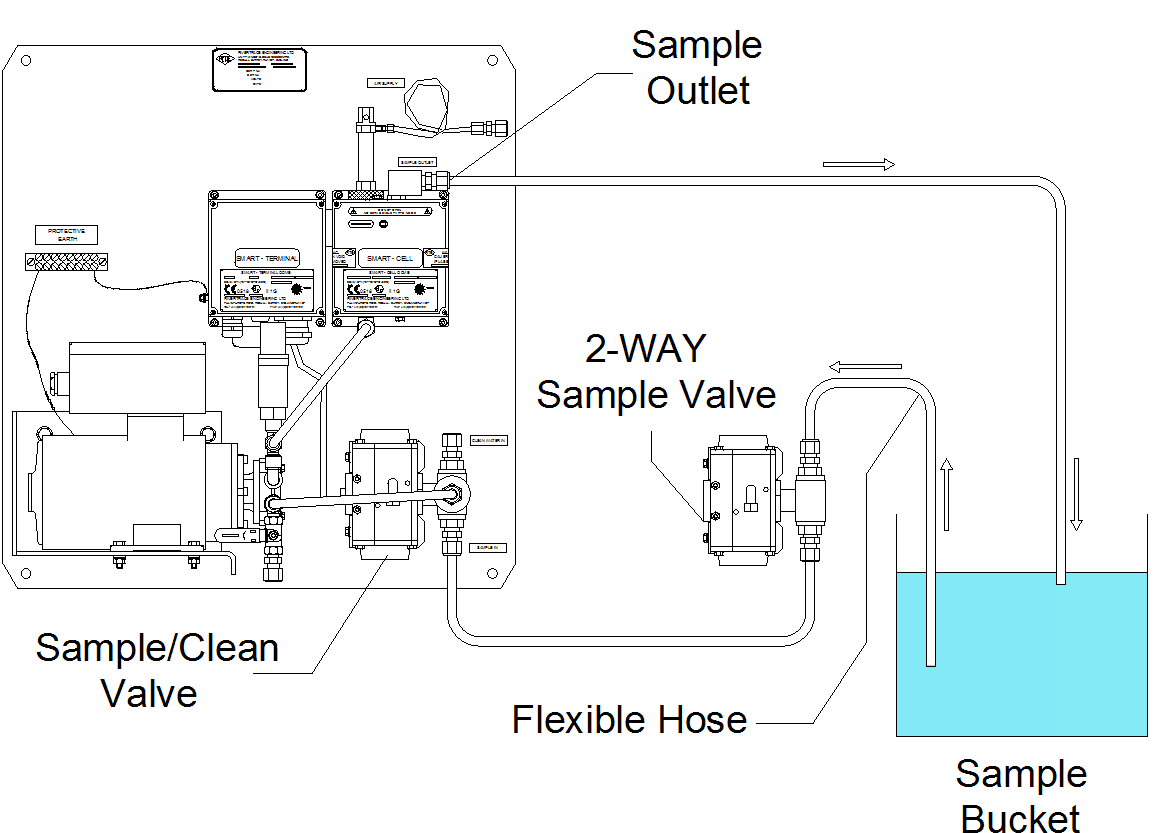

The oily water connection should be removed from the 2-way valve before the VPC and a suitable flexible hose should be connected in its place. The hose should be routed into the empty drum. The drain connection from the measuring cell should be removed and a suitable flexible hose should be connected in its place. The hose should be routed back into the empty drum. Fill the drum with clean potable water to approximately of 2/3rd of the drum.

Please see image below;

To create a positive head prior to the pump, we advise positioning your sample bucket at an elevated position above the VPC.

At the Smart ODME computer change the settings to the following:

- Flowmeter 1 from AUTO to MANUAL and set a Manual Cap1 of 200 M3/h

- Ships Speed from AUTO to MANUAL and set a Man. Speed of 10 kn

Enter Oil Discharge mode and follow the on screen information to carry out a discharge ensuring that both hoses stay inside the bucket at all times. On the ODME computer display, ensure that the ODME screen shows a litres/nm discharge. The ppm will reflect the water in the drum.

After the preparation cycle, the auto-clean wiper will be operated periodically, every 10 minutes.

With the suction hose under the surface of the water inside the barrel, slowly inject the oil into the suction hose. At the ODME computer, check that the ppm and litres/nm discharge increase and the overboard valves change state when 1000ppm is reached or the litres/nm value exceeds 30 litres/nm.

At the end of the test, replace all pipe work and change the settings in the Computer module back to their original settings.

This test does not check the PPM accuracy of the measuring cell.