Checking the ODME Flow meter paddle assembly (RT14 totaliser).

A simple guide on checking the condition of your paddle wheel assembly.

Checking the Rotor

Isolate all flow, along with isolating all power to the ODME system before remove the flow meter from the discharge pipe. You must then check that the rotor is very clean, free spinning and that all lobes of the paddle wheel are present and correct. The slightest friction during this rotation can cause the wheel to jam in operation give a zero flow calculation.

If your rotor is damaged, worn or restrictive to turn, the rotor will need replacing.

Replacement rotor kits can be purchased from Rivertrace and include the spindle. it is always beneficial to include a photograph of the required part when ordering to ensure that the correct parts are supplied.

Details of rotor removal can be found here should it need to be replaced.

Checking the reed switch

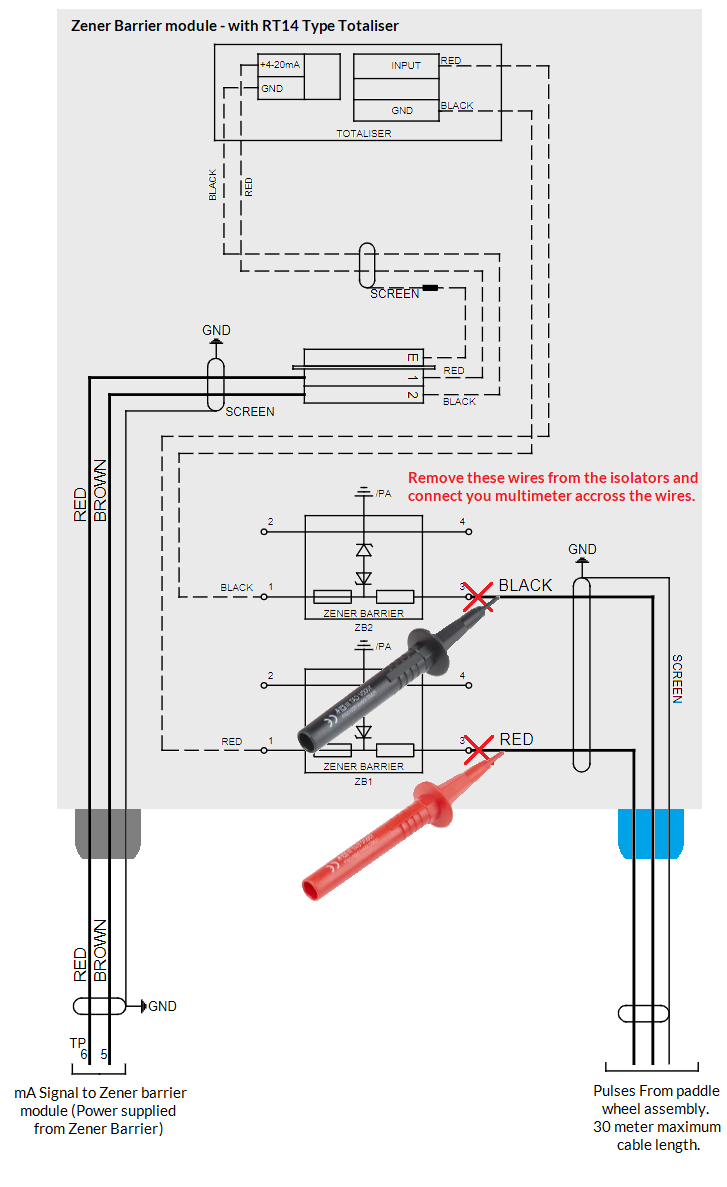

If your rotor is in good condition, you must now check that the paddle wheel assembly is giving pulses when the rotor is manually rotated. This is achieved by removing the wires from the paddle wheel assembly within the flow meter totaliser module and connecting a multimeter across the wires, looking for continuity.

When the paddle wheel is rotated by hand, you should see the continuity momentarily pulse with each revolution of the rotor.

If you are not receiving the pulse, the complete paddle wheel assembly will need replacing.

If your rotor is in good, clean condition and you are receiving pulses when measured with a multimeter, your paddle wheel assembly is working correctly.