OCD CM/CW error codes

During normal operation or when you have replaced the cell and chip you may get an error code displayed on the unit. This document will outline their meaning.

Other than "bC", it is normal to see error codes displayed during the initial power-up of the analyser. Error codes will be displayed whilst the LED intensity is automatically regulating. There is no convention which error codes may be displayed at this stage.

Error codes are only a concern when they remain at the display permanently after power-up, whilst clean water is inside the measuring cell.

OVER RANGE. This error is displayed when the oil content exceeds the 40ppm maximum PPM range. This usually indicates a very dirty sample but if you are sure that the sample is below 40PPM, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.

SOLIDS HIGH. This error is displayed when the Solids content is excessively high or there is air in the sample.

It is useful to rule out excessive sample contamination by using the "Sample contaminant identification procedure".

If you are sure that the sample is clean, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.

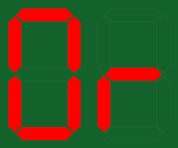

BAD CALIBRATION. This error is displayed a clean water calibration has been performed with a dirty sample within the measuring cell or a dirty glass tube.

You must clean the measuring cell, following the measuring cell cleaning procedure and then flush the cell with fresh water for 30 minutes before performing a "Zero" by pressing and holding the "Set / Zero" button whilst fresh water is flowing through the measuring cell.

If this fails then the tC value reset procedure must be followed before performing the Zero process once more. If this fails then the calibrated parts should be replaced.

ERROR 1. This error is displayed when the glass tube is dirty or there is excessive air, oil or solids within the sample causing the light to be restricted to the scatter detectors.

It is useful to rule out excessive sample contamination by using the "Sample contaminant identification procedure".

If you are sure that the sample is clean, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.

ERROR 2. This error is displayed when the glass tube is dirty or there is excessive air, oil or solids within the sample causing the light to be restricted to the tC detector.

It is useful to rule out excessive sample contamination by using the "Sample contaminant identification procedure".

If you are sure that the sample is clean, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.

ERROR 3. This error is displayed when too much light is received by the scatter detectors. This is usually caused by air or poor set up.

It is useful to rule out excessive sample contamination by using the "Sample contaminant identification procedure".

If you are sure that the sample is clean, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.

ERROR 4. This error is displayed when too much light is received by the tC detector. This is usually caused by poor set up.

If you are sure that the sample is clean, the measuring cell cleaning procedure should be followed and then the tC Value reset. If this fails then the calibrated parts should be replaced.