OCD CW Overview

A detailed look at the OCD CW and its functionality.

Overview

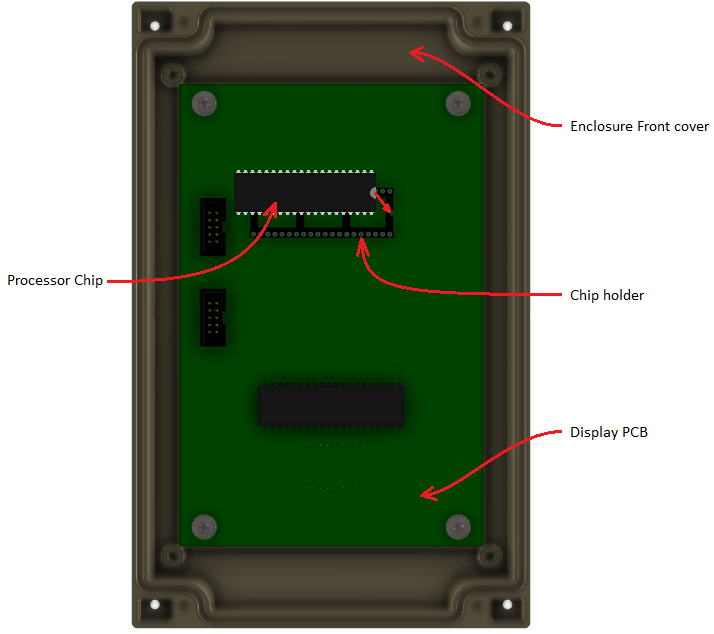

The OCD CW is a simple yet effective oil-in-water analyser for industrial applications. With a range of 0 to 99ppm and mild solids discrimination, handling up to circa 50ppm of Fe3O4, the OCD CW is designed for a multitude of applications, ranging from relatively clean process and cooling water monitoring through to run-off / Groundwater monitoring. The OCD CW has no memory for recording events or PPM, however, an analog output is available for use with an external recorder or remote display.

The OCD CW remains a favourite for the measurement of groundwater leaving large hard standing areas such as runways, bunded tank farms and large car parks into local rivers and waterways. Boiler condensate can also be monitored with the addition of a cooler.

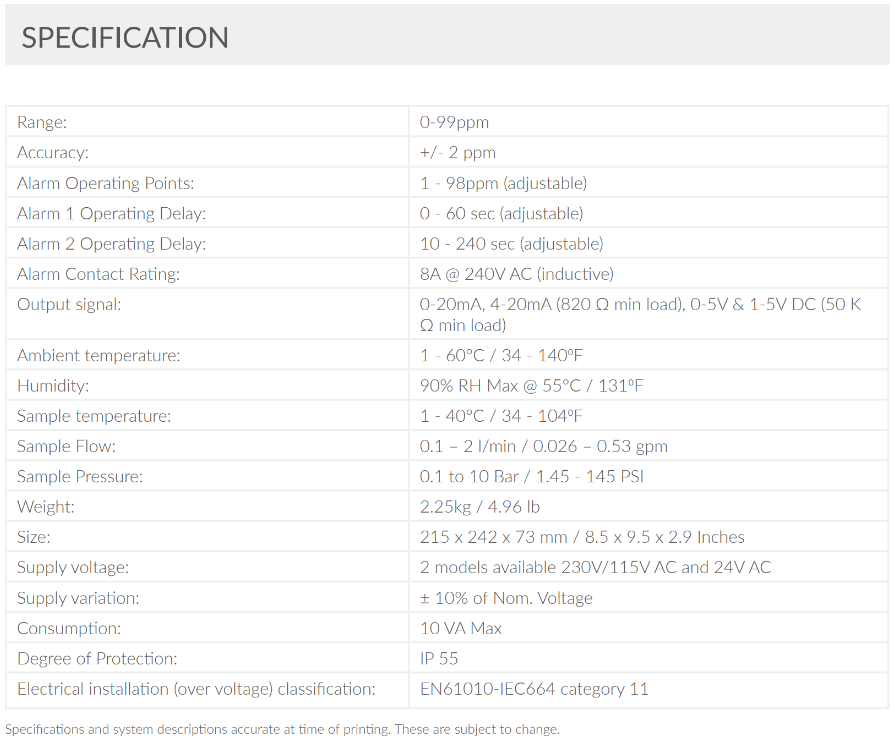

Monitor Layout

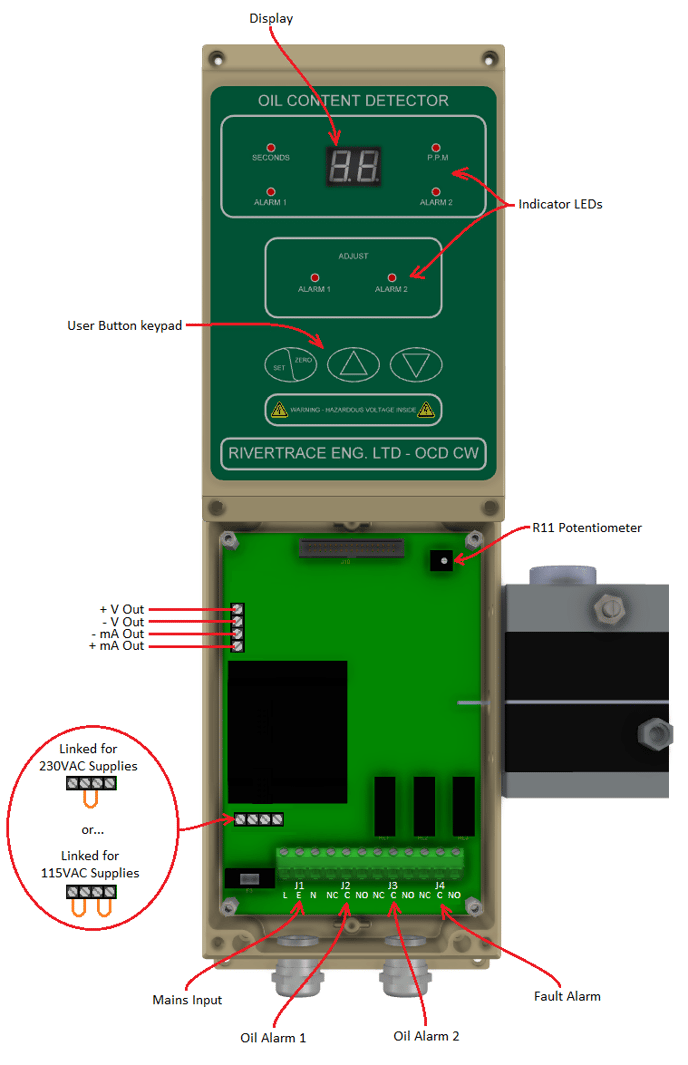

The OCD CW is split into two parts. The left side is the control module and is the user interface for the monitor. The right hand side is the measuring cell that the sample flows through to be analysed.

Control Side

Within the control module, there are the following customer connections:

-

- Oil alarm 1 relay - User adjustable set point and delay time

- Oil alarm 2 relay - User adjustable set point and delay time

- Fault alarm relay - Changes state if an error code is displayed.

- 4-20 / 0-20 mA Output - User adjustable between 0-20mA and 4-20mA

- 0-5V Output - User adjustable between 0-5VDC and 1-5VDC

- Input voltage selector - To be set during installation, dependent on supply voltage.

- Mains Input terminals - 115VAC / 230VAC as standard. 24VAC Available.

Cell Side

The measuring cell contains the electronic and optical components used for analysing the sample.

The Sample is fed into the measuring cell inlet via the 1/4" BSP Female orifice at the bottom of the assembly and then passed to the drain via the 1/4" BSP Female outlet orifice at the top, right side of the assembly.

A knurled cap at the top of the assembly gives the user access to the glass tube for maintenance purposes. As standard, a bottle brush should be used to clean the inside of the glass tube.

A desiccator is fitted in the front face that is designed to remove humidity and moisture from the sealed dry space within the cell that houses the electronics. The desiccator is filled with either blue or orange silica granules and must be replaced annually or when the granules turn white in colour, visible from a clear window in the front of the desiccator assembly.

The throttle screw is designed to restrict the outlet flow of the measuring cell. This restriction at the outlet increases the sample pressure within the measuring cell and helps to compress any small air bubbles within the sample to reduce the impact of measurement accuracy.

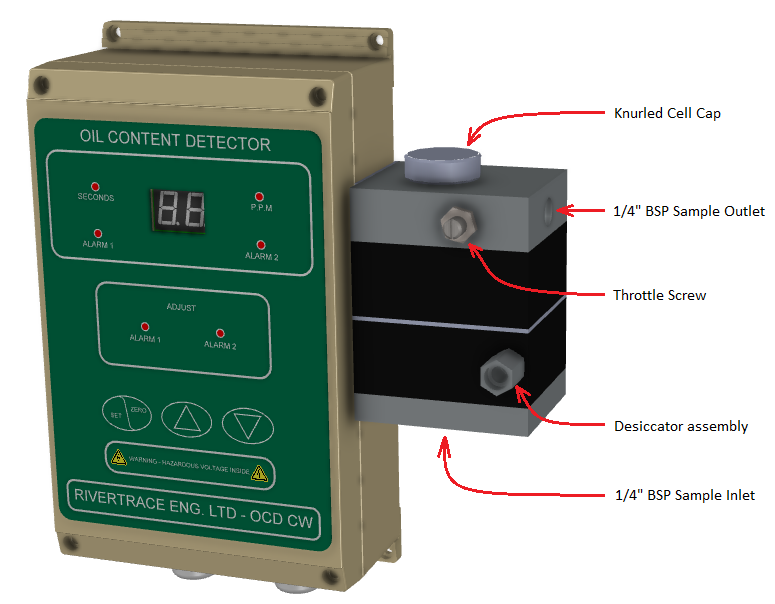

Calibration

To renew the calibration of an OCD CW there are two options. The complete OCD CW can be returned to Rivertrace for factory assessment and recalibration or spare calibrated parts can be purchased for replacement by the user.

The calibration for each measuring cell is stored on a small processor chip. A processor chip is supplied with each measuring cell and these must remain installed as a matched pair. If the cell is replaced without swapping the processor chip alongside, the calibration is void.

The processor chip must be installed in the display PCB within the control module. It is crucial that the chip is inserted into the chip holder in the correct orientation, identified by a "D" mark on both the processor chip and the PCB.

Once the new parts are fitted, the power to the LED within the measuring cell must be adjusted whilst clean water is within the measuring cell. We call this "Adjusting Tc (Transmission)". Full instructions on replacing the cell and chip can be found here.

It is important to remember to adjust the Tc value if the main PCB is replaced too as the power source for the LED is located on the main PCB.

Optional Extras

The main cause for failure with optical analysing equipment is fouling of the optics. As standard, a bottle brush is supplied with the OCD CW to clean the glass tube with as required. To address this issue, the OCD CW can also be supplied with an "Autoclean" system. This system automatically cleans the cell internals. The frequency of the clean is user adjustable.

We strive to meet the needs of our customer's unique applications. For this reason, we also offer this monitor as part of a bespoke system, designed around the customer, as with all Rivertrace products.

Below are some examples of bespoke items that have been included in our designs, alongside the OCD CW.

- 230VAC Mini compressor For applications requiring an Autoclean system but without compressed air availability.

- Stainless Steel mounting frame for a free-standing installation.

- SCU (Sample Conditioning Unit) for sample conditions that fall outside of our standard specification requirements.

- Sample Cooler for applications where the sample being received by the analyser is outside of our standard specification requirements.

- Vortex Enclosure Cooler for reducing the ambient temperature around the analyser in applications where extreme ambient temperatures fall outside of our standard specification requirements.

- Enclosure Heater for cold environments where freezing may cause damage.

- Stainless Steel sunshade to reduce the temperature around the analyser in exposed applications.

- Weatherproof enclosure to protect the analyser and associated equipment from severe weathers, flooding and deluge and of course acting as a mechanical protection against impact or tampering.

- Sample pressure regulators and PRVs for ensuring that the sample entering the system cannot cause damage should pressure spiking or high pressures occur.

Each bespoke system is supplied with a manual and technical drawings to support as standard and arrives to the customer as a finished product.

On-Site verification

Rivertrace offer an on-site calibration verification kit. The kit consists of two, very accurately produced samples that when poured into the measuring cell, display predetermined values. This allows the user to have confidence in the equipment.

Maintenance

Weekly

• Ensure that the monitor reads 0ppm with clean water passing the cell.

Monthly

• Check the colour of the desiccator, If the desiccator granules appear white, the desiccator will need replacing.

Yearly (units with Autoclean only)

• Replace the wiper ring on the Autoclean.

Standard Spare Parts