OCD Xtra overview

Exceptional real-world performance in measuring the free oil content of water, containing high solids contents.

Overview

The OCD Xtra is our go-to analyser for industrial oil-in-water monitoring. Designed for the harshest of conditions, robustness and reliability is essential, along with the ability to remain accurate whist the sample contains high concentrations of rust, drilling mud, sand and other solid contaminants.

The OCD Xtra utilises a unique, dual wavelength absorbance measurement principle and does not depend on fluorescence technology. The result is that chemicals, BOP fluids and other substances that are transparent in water yet fluoresce, will not cause false high or inaccurate readings that will trigger alarms and hinder process, or worse still, allow free oil to pass undetected.

Main applications are oil in produced water, oil in process water, oil in run-off water. These applications are prone to containing solid particulates and other chemicals that may hinder scattered light or fluorescence measurement techniques.

The standard out-of-the-box factory calibration will typically give an accuracy of +/-5ppm within global dischargeable ranges. This accuracy can be vastly improved if calibrated using site specific oils. To improve accuracy further, the calibration can be adjusted on-site to match laboratory results. This process effectively tunes the calibration to suit site specific sample properties, often returned accuracy +/-1ppm, reliably.

All wetted parts are machined in 316 stainless steel as standard and are also available with traceability certificates. We also offer wetted parts machined in exotic materials on request, such as Monel, Super Duplex, Inconel, SS904 to name a few. NACE compliance is also on offer.

Our specifications are recorded from real-word results and are not fabricated under laboratory conditions. This ensures that we meet expectations and deliver the performance that we state on our specification sheet to the application.

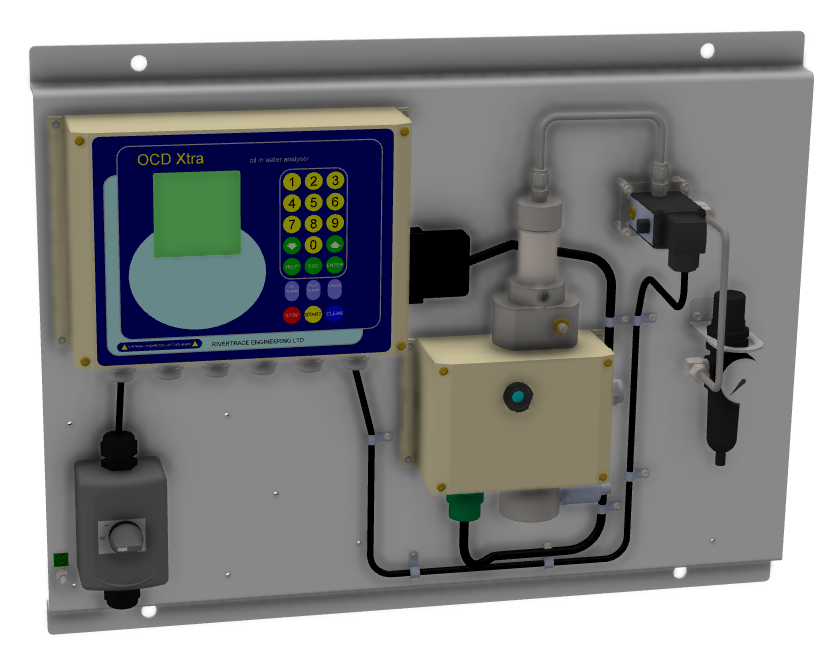

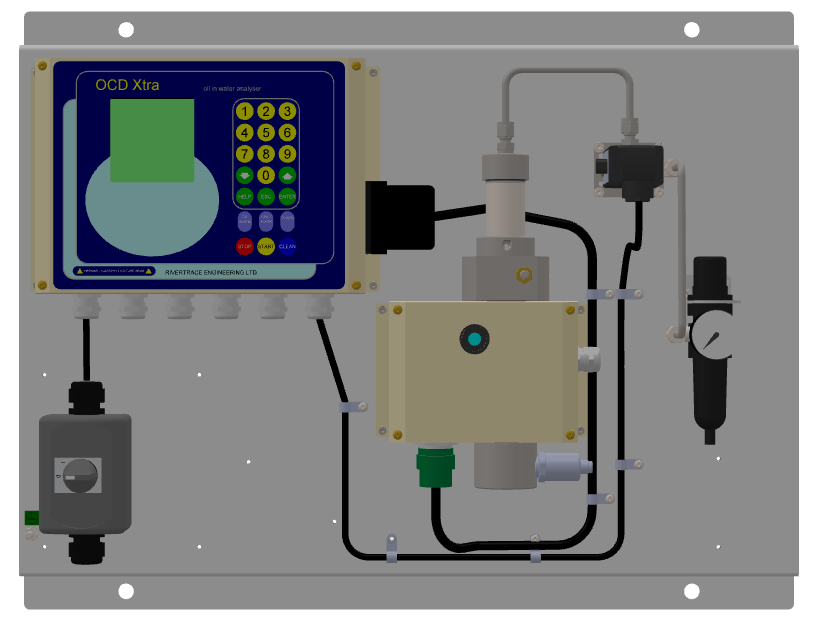

Analyser layout

The OCD Xtra consists of three key parts that are all mounted on a 5mm powder coated aluminium backplate.

Computer Module

The computer module is the user interface of the analyser alongside being the main processing power and holding the calibration for the measuring cell.

Underneath the front button panel there are two PCBs, both of which impact the calibration of the measuring cell, alongside an LCD Display. This is also where all customer terminations are made other than the power supply, which is wired through an external mains isolator switch to ensure engineers can safely work on electrically isolated equipment.

There are three variable potentiometers on the main PCB that are sealed. Adjusting these potentiometers will damage the calibration, resulting in the analyser needing factory calibration at Rivertrace.

On the Main analog PCB, you will find the following connections:

- Mains Input (Post external Mains isolator switch)

- Alarm 1 relay - SPDT Volt free contacts that change state when the PPM exceeds a user adjustable set point.

- Alarm 2 relay - SPDT Volt free contacts that change state when the PPM exceeds a user adjustable set point.

- Fault Alarm relay - SPDT Volt free contacts that change state if a fault should occur or the sample pressure is outside of its required range (Can be used to prevent dry running of external pumps).

- CON 1 - Pump control output should the application require the need to start and stop a sample pump.

- Remote Start / Stop input - Terminals that can be used to remotely start and stop the analyser remotely. These contacts should be connected to remote, volt free N/O contacts that close contact when the system is required to run. Screened cable should be used for this connection.

- 0-5VDC Output - Output that allows remote equipment to detect the current PPM value. 0VDC equates to 0ppm and 5VDC equates to 200ppm as standard. However, this scaling is adjustable by the user.

- 4-20mA Output - Output that allows remote equipment to detect the current PPM value. 4.00mA equates to 0ppm and 20.00 equates to 200ppm as standard. However, this scaling is adjustable by the user.

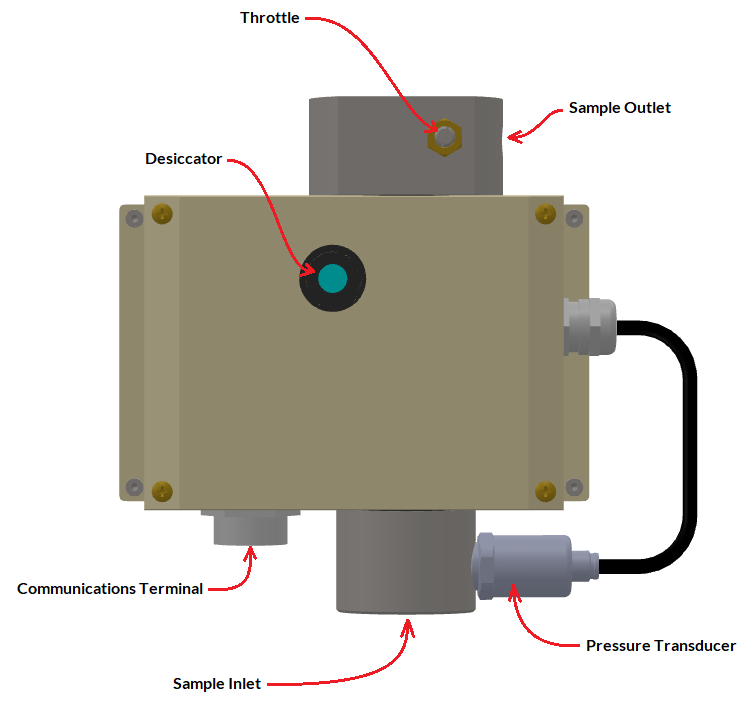

Measuring Cell

The measuring cell uses dual wavelength absorption technology to determine the oil content. The light is directed across a clear glass tube that the sample flows within and is measured on the opposite side. There are no serviceable parts inside the measuring cell (Other than the desiccator) and tampering within this enclosure will hinder measurement accuracy.

Desiccator

Mounted in the front cover of the measuring cell is the desiccator. The desiccator removes ambient moisture from the internal atmosphere of the cell, preventing damage to the electronics and condensation on the external walls of the glass tube allowing accurate measurement. This is the only serviceable part of the measuring cell and must be replaced when the blue window turns clear / white.

Pressure Transducer

At the inlet of the measuring cell, a pressure transducer is positioned to measure the sample pressure. If the pressure falls outside of the permissible pressure tolerance (0.5 Bar to 10.0 Bar) , an alarm is triggered, the fault alarm relay will change state and any pumps controlled by the "CON1" output will be stopped to prevent damage.

Throttle

The throttle screw is positioned on the cell outlet block and is designed to restrict the outlet, increasing the pressure within the measuring cell to an optimum pressure of 3 Bar. This is especially useful if air is present within the sample as a higher cell pressure compresses the air bubbles and reduces the impact on measurements. Turning the throttle clockwise will restrict the flow path and increase sample pressure whilst turning the throttle anticlockwise will decrease sample pressure.

Communications Terminal

The communications terminal is a bayonet type multi pin socket that is used to pass all analog signals out of the measuring cell and on to the computer module.

Safe area measuring cells have communication cable fitted as shown below.

Sample Inlet and Sample outlet

The sample inlet is at the bottom of the measuring cell, and the outlet is at the top. The reason why the sample must pass the cell from bottom to top is so that any air within the sample can naturally leave the outlet without being trapped inside the glass tube. The inlet port is 3/8" BSPT and the outlet port is 1/4" BSPT, although adaptors can be supplied to suit any connection.

It is critical that the computer module, and measuring cell (including all internal PCBs) remain in use together. These are calibrated sets and miss matching these parts or swapping individual PCBs will result in the calibration being lost.

If you wish to renew the calibration of the OCD Xtra, the Computer module and measuring cell can be swapped out on site for newly calibrated parts. The computer module and measuring cell can also be returned to Rivertrace for recalibration or additional oils types to be added to the calibration.

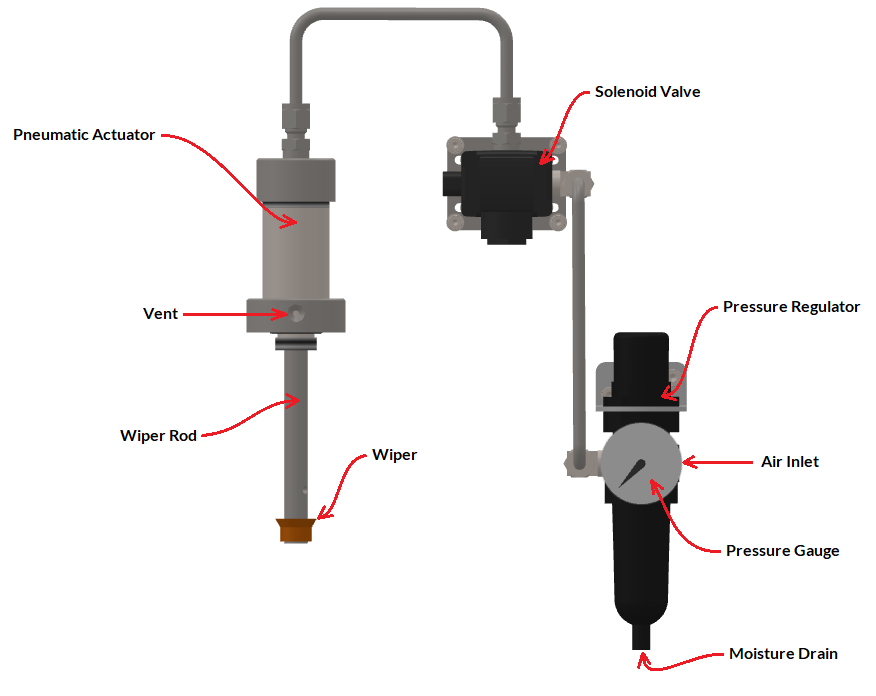

AutoClean system

With all optical analysing equipment, regardless of manufacturer or type of analysis, keeping the optics clean is paramount to success. With around 40 years of experience in sample analysis using optical methods, Rivertrace have experimented with many different methods to automatically clean the equipment and we have found that the most effective method is without a doubt mechanical. This is a very simple system that is automatically controlled by the OCD Xtra computer module. The wiper will clean the inside of the glass tube in adjustable intervals within the user menu. For applications that are more likely to foul optics, the frequency of the cleaning can be increased. The AutoClean is fitted as standard to all OCD Xtra systems. The wiper ring should be replaced annually for optimum performance.

Routine maintenance

Before each week of use

• Check that the analyser reads 0ppm with clean water flowing through the measuring cell. (If The PPM will not drop to 0ppm, this indicates that the cell tube will need cleaning).

• Check the colour of the desiccator window. If the window is blue, moisture levels are within operational limits. Replace Desiccator if colour is either pink or white.

Yearly

• At yearly intervals (or where necessary) the wiper ring on the Autoclean assembly should be replaced. This can be ordered from Rivertrace directly under the following part number: 103136

• Replace the desiccator.

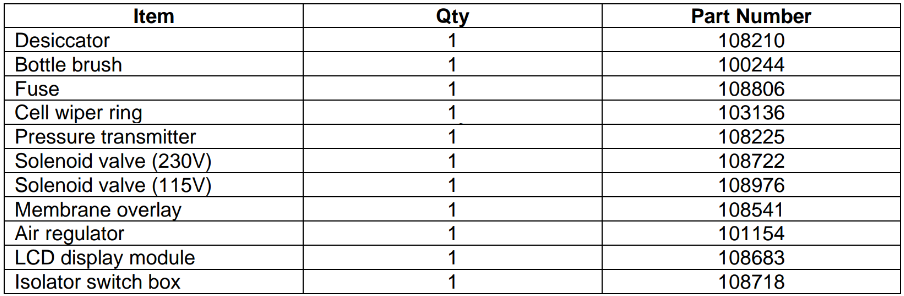

Standard spares

Customisation and bespoke systems

Due to the performance of the OCD Xtra, end users often need this system working in remote and extreme environments. For this reason, the OCD Xtra is often integrated into bespoke "Systems" that handle site specific requirements. These additions include (But not limited to):

- Exd Flameproof Enclosure for hazardous areas, conforming to ATEX requirements in Zone 1 potentially explosive atmospheres.

- Stainless Steel mounting frame for a free-standing installation.

- SCU (Sample Conditioning Unit) for sample conditions that fall outside of our standard specification requirements. This is highly recommended for maximum accuracy, repeatability and reliability of the analyser. More information on sample conditioning can be found here.

- Sample Cooler for applications where the sample being received by the analyser is outside of our standard specification requirements.

- Vortex Enclosure Cooler for reducing the ambient temperature around the analyser in applications where extreme ambient temperatures fall outside of our standard specification requirements.

- Enclosure Heater for cold environments where freezing may cause damage.

- Stainless Steel sunshade to reduce the temperature around the analyser in exposed applications.

- Weatherproof enclosure to protect the analyser and associated equipment from severe weathers, flooding and deluge and of course acting as a mechanical protection against impact or tampering.

- Sample pressure regulators and PRVs for ensuring that the sample entering the system cannot cause damage should pressure spiking or high pressures occur.

Each bespoke system is supplied with a manual and technical drawings to support as standard and arrives to the customer as a finished product.