Smart ODME Pressure errors

Guidance on how to overcome pressure related errors during a discharge.

Overview

If your ODME system flags either "Pressure over range" or "Pressure under range" alarms during a discharge, there are two possible causes for this.

1. The pressure at the pressure transducer is actually over range or under range.

2. The pressure transducer or associated circuitry are at fault.

Identifying the issue

To differentiate between the two possible causes of your pressure error, a self-test should be carried out. This will check that your pressure transducer and associated circuitry is behaving normally or if this is where the problem lies.

If the self test fails on pressure related issues, detailed help can be found here.

If the self test passes, the pressure issue during your discharge is likely to be caused by the sample at the pressure transducer actually being out of range.

Try the following steps before retesting:

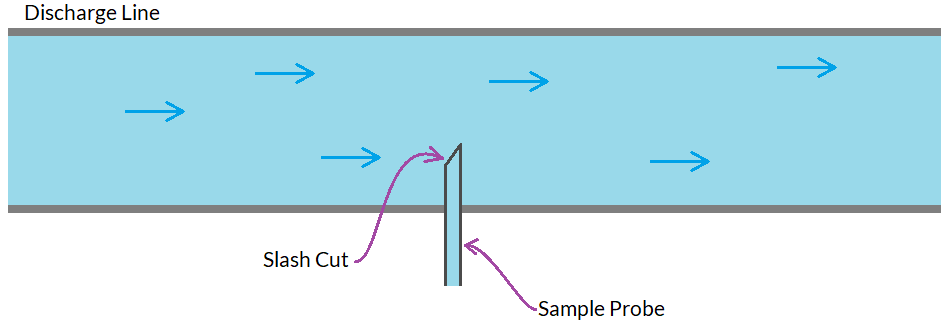

- Check that the sample probe is inserted into your discharge line in the correct orientation. The open slash cut of the probe should be facing the flow.

- Ensure that your sample line and your sample return lines are clear, free flowing and have no leaks. Check for valves that may have been accidently closed (Crew report that steaming the sample lines often helps here, ensuring not to allow steam to reach the ODME equipment).

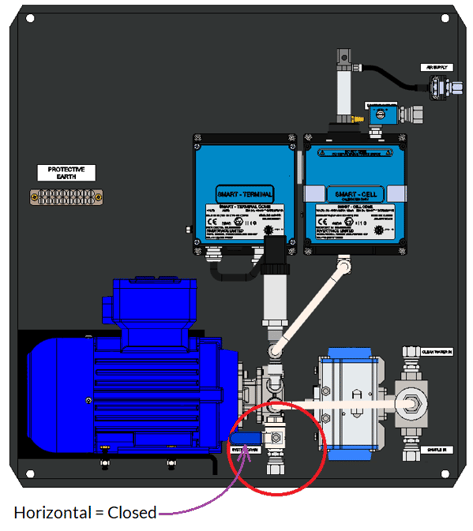

- Ensure your system drain valve is closed at the VPC.

- Ensure your discharge pumps are running prior to starting the discharge at your ODME system.

- Make sure your sample is air free with no foaming as this can cause cavitation at the ODME Sample pump and a decrease in pressure.